Trucks with tipping bodies find their use in numerous applications, mostly relating to mining, transporting or moving minerals, cement, coal, construction material, sand, etc. from one place to another. For instance, a dumper truck will use body tipping to unload the goods. While some vehicles use simple tipping, few other applications require more complex forms of tipping such as three-way tipping.

As a standard practice, hydraulic packs are used to provide required tilt angle to these vehicles. While tipping is a very common activity in the industry, several factors, which can compromise the safety of the tipping vehicle during operation are important to consider.

Any mishap will not only damage the vehicle but will also cause damage to the hydraulic pack and harm to the individuals operating the vehicle and present in the vicinity leading to monetary losses and legal complications.

Before we discuss how a tilt switch can help prevent these accidents and consequent damage. Let us have a look at different factors which can lead to an accident while tipping:

- Exceeding Safe Angle: During tipping, a center of gravity of the vehicle constantly shifts. If the tipping is carried out beyond a certain safe angle, the vehicle might become unstable and topple.

- Overloading: If the vehicle body is loaded with more material than permissible, then the safe limits of operation will change and the vehicle will be prone to toppling even before the maximum safe limit is reached.

- Inclined Surfaces: When a vehicle is tipping on an inclined surface, it is prone to lose its stability faster.

- Moving While Tipping: If the vehicle is in motion during tipping, or brakes are suddenly applied to a moving vehicle while it is tipping, it might become unstable.

As we have discussed briefly earlier, exceeding safe angle can lead to:

- Damage to the hydraulic pack.

- Toppling of the vehicle leading to damage to the vehicle.

- Physical injuries to the operators and individuals in the vicinity.

About Tilt Switch:

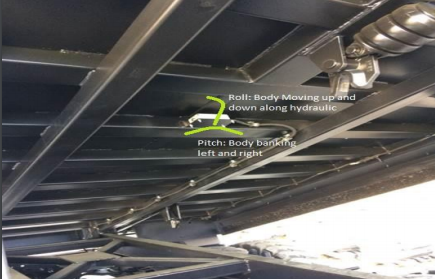

A Tilt Sensor or Tilt Switch is an inertial device which monitors the angles in longitudinal and lateral directions of any platform to which it is attached. When the platform is oriented the sensor in the device generates a signal proportional to the orientation. This signal is processed inside a microprocessor and the digital output of the angle is given out on serial interfaces. The Tilt Switch offers an option for configuration of safe operation angle limits – the relay is activated when the platform angle/booming angle reaches these safe operation angle limits. The relay connects with buzzer for operator attention and/or solenoid valve to stop the hydraulic operation altogether. In case of applications where the vehicles are tipping on a slanted platform, the device compensates for the tilt of the ground surface.

A tilt switch or a tilt sensor is a compact, easy to use the device and proves to be a cost-efficient way of avoiding accidents while tipping dumper trucks or other vehicles in all kinds of operating conditions.